PD940 DIPSTICK

Level, conductivity and temperature transmitter, Analogue current output: 4-20 mA, Digital I/O, P-NET via RS485

• Compact sanitary design – designed for the food industry

• Level, conductivity and temperature sensor in a single unit

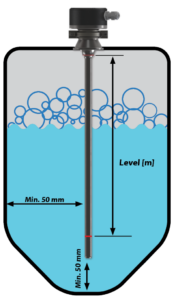

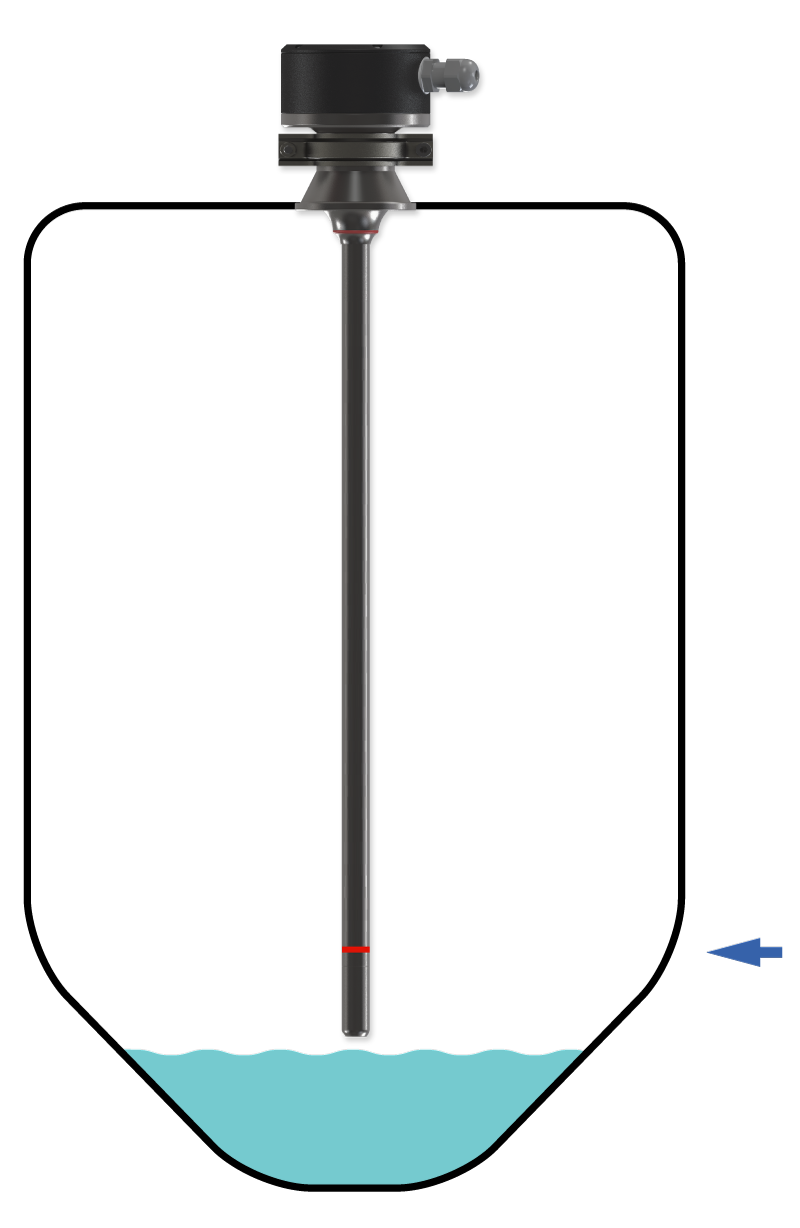

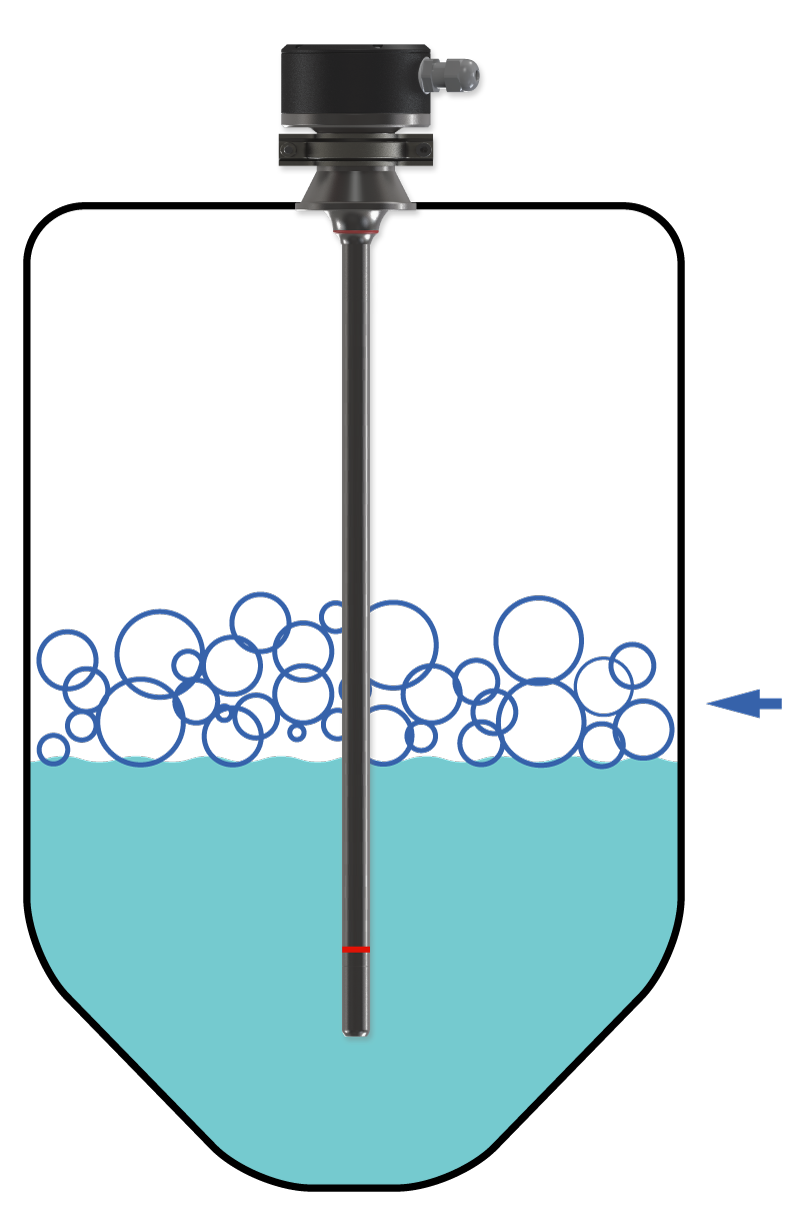

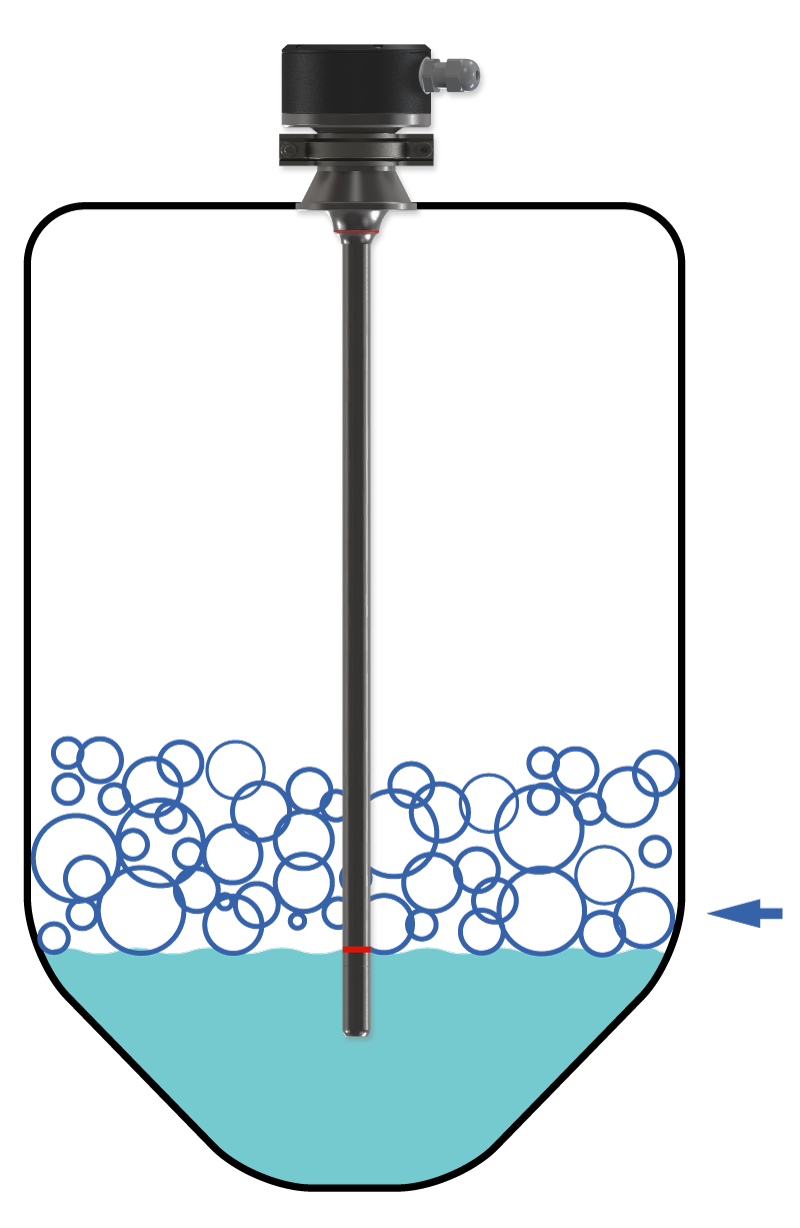

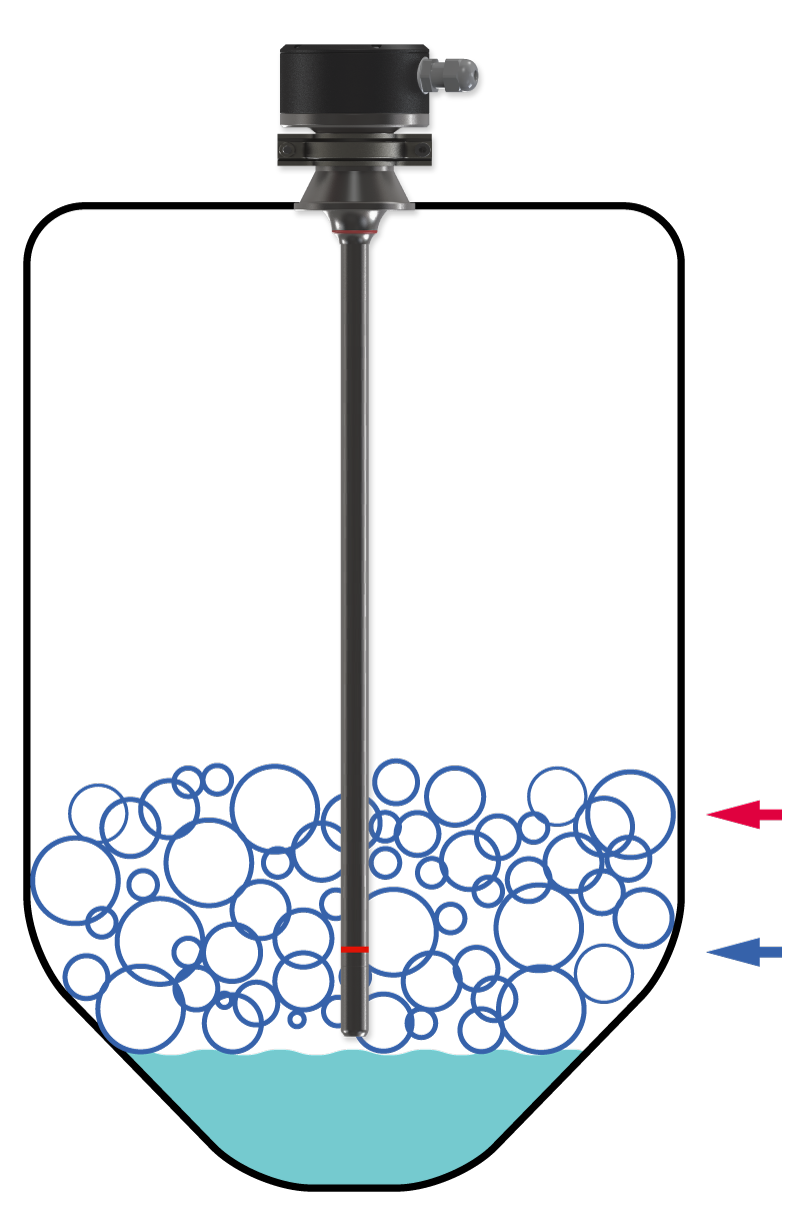

• Handles foam in liquid – only the equivalent liquid of the foam is included

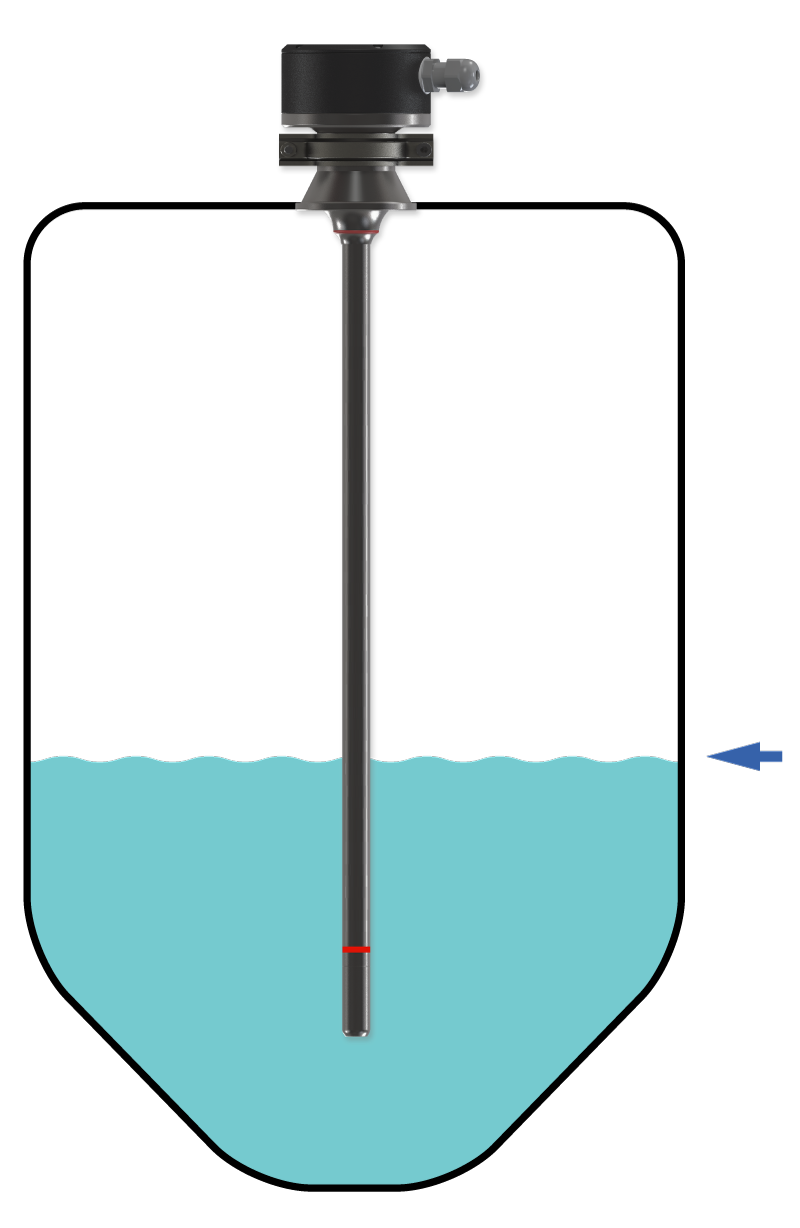

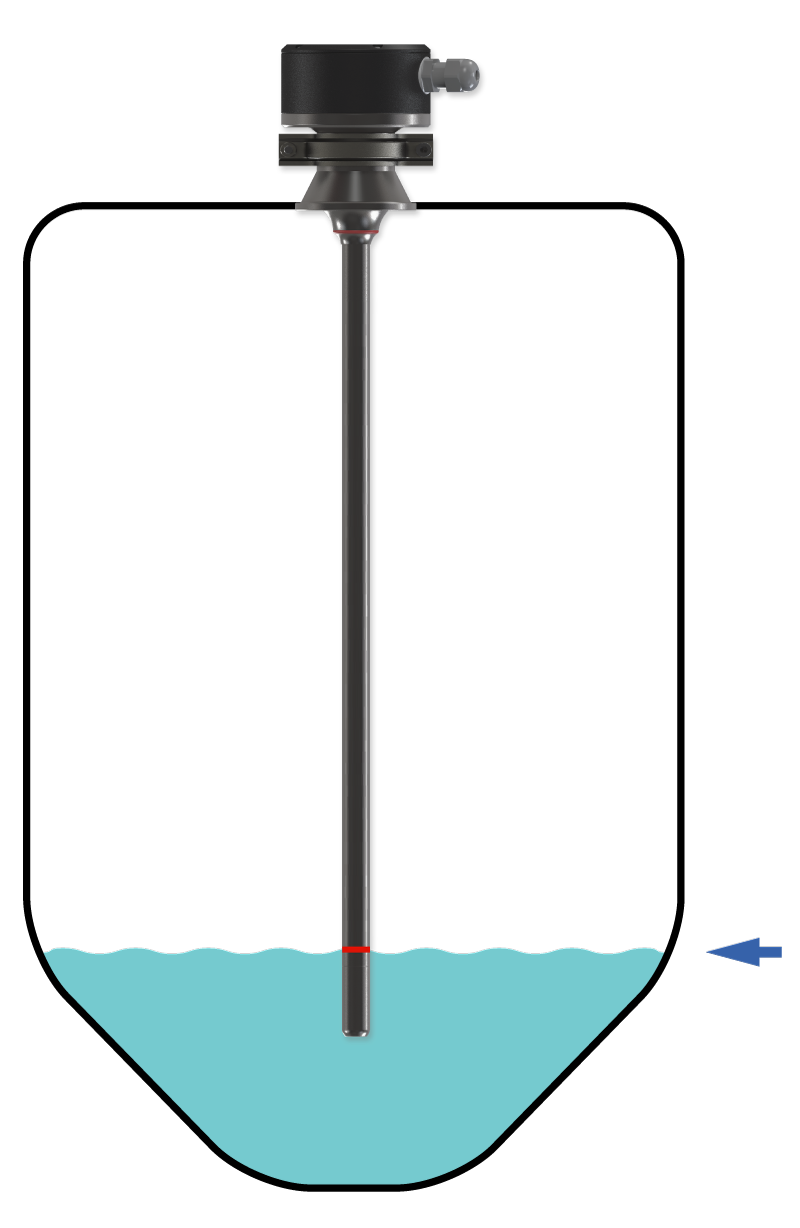

• Reliable continuous level measurement

• Designed for top mounting in vessel

• Flexible configurations to suit your specific application

• Conductivity sensor

• Temperature sensor, process temperature range 0 °C to 100 °C

• Analogue current output: 4-20 mA

• Digital I/O

• Programmable in COPP

• P-NET via RS485

Loading...

Product Description

- Compact sanitary design – designed for the food industry

- Level, conductivity and temperature sensor in a single unit.

- Handles foam in liquid – only the equivalient liquid of the foam is counted

- Reliable continuous level measurement

- Designed for top mounting in vessel

- Flexible configurations to suit your specific application

- Conductivity sensor

- Temperature sensor, process temperature range 0 °C to 100 °C

- Analogue current output: 4-20 mA

- Digital I/O

- Programmable in COPP

- P-NET via RS485

1. | 2. | 3. | 4. | 5. | 6. |

PD 940 Datasheet

PD940 DIP-STICK Flyer

EU conformity Level sensor