Innovative Design

The philosophy behind this innovative range of modules is to provide the systems designer with a highly flexible means of constructing a local cluster of I/O devices, consisting of a single or multiple intelligent and programmable units. Each cluster would normally include one “Simple” P‑NET Interface module. This provides a connection between RS485 P-NET (the rest of the system) and Light-Link P-NET, which is the means of Fieldbus communication between the local modules. Thereafter, virtually any number of I/O modules of any desired type, can be clipped together to form the local requirement. Alternatively or additionally, further programmable modules may be included, each of which could provide an interface with P-NET (RS485), RS232, Ethernet (10 Mb/s). As the family grows, other interfaces including integral Modem, GSM, GPS, and some of the other IEC approved Fieldbuses, will be made available.

Minimum Wiring

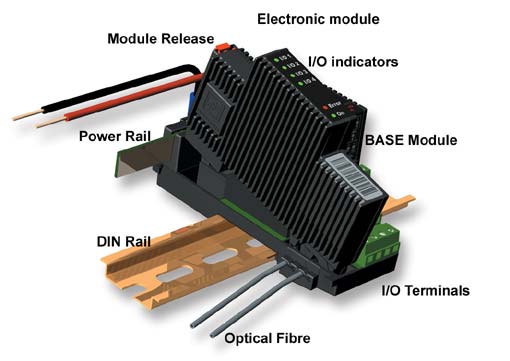

Due to their unique construction, individual Base modules are simply mounted side by side on the DIN rail. However, there is no need to perform any communication wiring between them, because this is achieved using multi-path fibre optic pipes, mounted on each side of every module. Furthermore, once the number of modules required has been mounted, power to each is provided, by clipping in a single Power Rail strip, thus eliminating further wiring. Due to the construction philosophy of reserving one terminal for each external wire, no additional wiring is required within the installation box or mounting panel. The module itself is an intelligent terminal block that enables direct connection of external signals without using a common terminal strip, which would traditionally have to be mounted in the bottom of the control panel. This significantly reduces the total cost, since no additional internal wiring is required for I/O signals.

Construction

Modules are made up of two parts – the electronics and the base module holding the terminals. The electronics block also mounts the I/O, power and error LEDs, and can be removed from the base module even when power is applied, and without interfering with the operation of the rest of the cluster (hot-swapping). In addition, inappropriate replacement is prevented by means of a special coding of the connector. Terminals are stacked on one side only, for easy access and minimum wiring area, and are designed for one wire per terminal. The elimination of “common” terminals means that any transducer/sensor/ actuator can be added/removed without affecting the connection of any other. The upper surface of the terminal part provides a means to attach a customised label relevant to the operation of the module, thus aiding wiring, commissioning and maintenance.

Versatility

The PD 600 series of devices consists of a versatile mixture of both standard input/output and special devices, and additional modules will be regularly added to the family. Coupling this with the ability to add local programmability and gateways, ensures that the Multi-master, Multi-net facilities offered by the P‑NET Fieldbus protocol can be fully utilised. Due to the fact that each M36 module offers a limited number of channels, ensures that local clusters can be designed to reduce unused channels to the absolute minimum. This in turn leads to minimising the cost and size of each cluster.

Environmental Factors

Physically, the modules are designed to operate within a wide range of industrial static or mobile environments, with a nominal power requirement of 24 Volts d.c. (min. 18 V, max. 32 V – see individual specifications), including polarity reversal protection, and an operating temperature range of –25 °C to + 70 °C. The module casings are moulded using UL approved plastic. The module design is ideally suited for mounting within standard industrial or domestic contact breaker boxes having an integral DIN rail and transparent access window. These can be readily obtained in a variety of sizes for both indoor and outdoor use, and when mounted, provide ideal viewing of the state of all the modules, without the need to remove any covers.

Usage

The compact nature and exceptionally wide power supply and environmental characteristics of the PD 600 family, make them ideal candidates for both machine and wide area plant use, as well as for stand-alone Fieldbus transmitters. The ability to form customised and programmable clusters of modules for distributed location around a plant or building, provides a virtually infinite variation of system designs. Furthermore, interconnection by means of P-NET means that this series of modules can be added to already installed P-NET systems using modules from other families, such as the PD 340 flow meter range, PD 5000 and PD 4000 programmable controllers, and the PD 3xxx range of intelligent I/O modules.

General Specifications

Dimensions (in mm):

Weight: 140 grams approx.

Power Supply: Nominal: 24 VDC, min. 18 VDC, max. 32 VDC. See individual manual section.

Operational Ambient Temperature: –25 °C to + 70 °C

Example networks:

Figure 1 Local or Plant/Building interconnection possibilities

Figure 2 Integration within PC LAN/WAN

Figure 3 Mobile Truck Mounted System Example